A stone factory in India uses a three-stage crushing process of "jaw crusher + cone crusher + sand making machine" to process basalt (compressive strength 250MPa) into aggregates of various specifications such as 0-5mm, 5-10mm, 10-20mm, etc. The output is 150-180 tons per hour, the finished product has excellent particle shape, and the needle-like content is less than 8%, which meets the IS 383 standard. The wear-resistant parts of the cone crusher are optimized to reduce maintenance costs by 30%. It is suitable for crushing high-hardness ores and provides high-quality sand and gravel aggregates for India's infrastructure.

The on-site equipment is reasonably graded, the equipment quality is reliable, mature technology is adopted, the production efficiency is high, the particle size of the finished product is adjustable, and finished products of different specifications and particle sizes can be processed.

The environmental protection configuration includes dust collector, spray device and noise reduction device. The dust collector can realize automatic dust cleaning, humidify the dry material and reduce the flying dust. The noise reduction device can effectively control the noise and reduce the noise pollution in line with the domestic environmental assessment standards, allowing customers to easily pass the environmental protection test.

The Indian basalt crushing production line adopts a fully automated control system, integrated with PLC intelligent central control and online monitoring equipment, to achieve full automation from feeding, crushing to screening. The parameters are adjusted in real time through the remote monitoring system to ensure efficient operation of the equipment and reduce manual intervention. The automation level is over 90%, the production capacity is increased by 20%, the energy consumption is reduced by 15%, and the production safety and stability are significantly improved, providing intelligent crushing solutions for the Indian building materials industry.

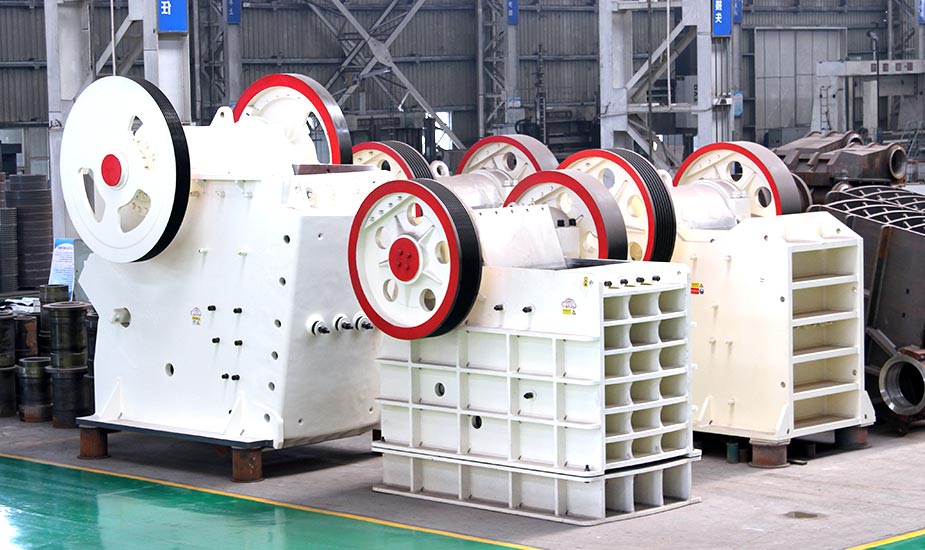

Jaw stone Crusher on structure and production efficiency present advanced modern technologies. Jaw stone Crusher can solve such problems of the existing jaw crushers as low production efficiency, difficult installation and maintenance. At present, Jaw stone Crusher is the ideal coarse crushing machine at domestic market.

Details

Vertical coal mill is an advanced coal grinding equipment with excellent performance and strong drying capacity. It integrates the functions of powder making, powder selection and drying. It is widely used in cement, coal, electric power and other industries, especially in the grinding industry. It has become the mainstream equipment in the powder making industry.

Details

The aggregate optimization system is the world's most outstanding dry sand making system. It adopts a highly intensive tower-style fully enclosed layout, integrating efficient sand making, particle shape optimization, stone powder control, grading adjustment, moisture content control, and environmental protection treatment. It not only significantly improves production efficiency, but also achieves a comprehensive improvement in various indicators such as machine-made sand particle shape, grading, and powder content, making the performance of machine-made sand comparable to that of natural sand, creating new opportunities and value for the development of the sand, gravel, cement, and concrete industry chain.

Details

Stone Crusher-sold by certified Suppliers,such as Jaw / Cone / Impact / Mobile Crusher,etc.

GET QUOTE

INQUIRY