The aggregate optimization system is the world's most outstanding dry sand making system. It adopts a highly intensive tower-style fully enclosed layout, integrating efficient sand making, particle shape optimization, stone powder control, grading adjustment, moisture content control, and environmental protection treatment. It not only significantly improves production efficiency, but also achieves a comprehensive improvement in various indicators such as machine-made sand particle shape, grading, and powder content, making the performance of machine-made sand comparable to that of natural sand, creating new opportunities and value for the development of the sand, gravel, cement, and concrete industry chain.

The grinding technology and waterfall shaping technology adopted in the tower sand making system make the finished sand and gravel grading reasonable and the particle shape round, effectively reducing the specific surface area and porosity of coarse and fine aggregates; at the same time, the dry powder removal technology is adopted to make the powder content in the finished sand adjustable and controllable.

The consumption of sand and gravel is large and the demand is high. The VU floor-standing machine-made sand and gravel system can process cheap and easily available "stone chips" and "melon stones" into high-value high-quality sand to replace natural sand, meet the huge market demand for high-quality sand, and generate huge profits.

The tower-type machine-made sand and gravel system adopts a fully enclosed transportation, production, and negative pressure dust removal design to ensure that the production is free of sewage, sludge, dust, and noise emissions, which fully complies with national environmental protection requirements.

The floor-standing type machine-made sand and gravel complete system is equipped with a central control system, which can control and detect the operation of all equipment online, quickly set and maintain excellent operating parameters, and ensure the quality of finished sand and gravel and the stability of the production line capacity.

The sand and gravel production line designed and configured by users in Luoyang area of Chengdu Xinshengrun Material has been officially put into production. The production line features: advanced equipment, reasonable grading, environmental protection and energy saving, high output value, high quality of finished products, and strong control ability.

Details

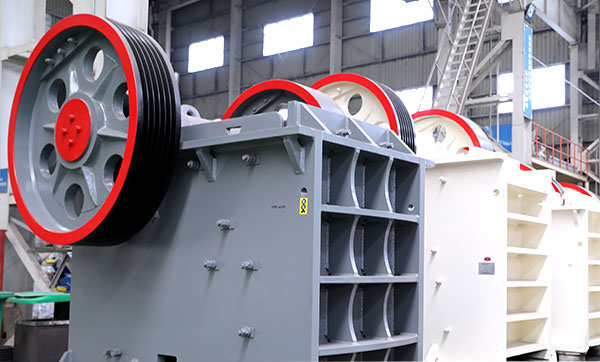

A stone factory in India uses a three-stage crushing process of "jaw crusher + cone crusher + sand making machine" to process basalt (compressive strength 250MPa) into aggregates of various specifications such as 0-5mm, 5-10mm, 10-20mm, etc. The output is 150-180 tons per hour, the finished product has excellent particle shape, and the needle-like content is less than 8%, which meets the IS 383 standard. The wear-resistant parts of the cone crusher are optimized to reduce maintenance costs by 30%. It is suitable for crushing high-hardness ores and provides high-quality sand and gravel aggregates for India's infrastructure.

Details

this river pebble sand making machine production line of Vietnamese users was really put into production in early 2017, and it has been nearly two years now. The level configuration between the equipment in the whole production line is reasonable, smooth operation, and stable production capacity, which is loved by the user

Details

Stone Crusher-sold by certified Suppliers,such as Jaw / Cone / Impact / Mobile Crusher,etc.

GET QUOTE

INQUIRY