Belt Conveyor adopts the modular component design, which greatly simplifies the production process, reduces the installation and disassembly difficulties, and saves the logistics cost. It can also shorten the preparation period and enhance the product quality. It is convenient for future maintenance

The main beam and supporting legs of B Belt Conveyor adopt modular design, which simplifies the production process and shortens preparation period. The modules are connected by bolts, reliable and convenient. The packaging is reliable

The structure of B Belt Conveyor is optimized: the main beam adopts C-shaped steel, which is lighter in weight but is of higher bending resistance (more secure) compared with channel steel of the same grade; the supporting leg is modified as Y-type, which makes the supporting more secure and greatly increases the stockpiling space.

The B Belt Conveyor uses high-efficiency external mounted electric drum and has its installed mode optimized, which is lighter and more convenient compared with the driving mode of common external motor reducing gear; compared with built-in electric drum, it has better heat dissipation performance

The B Belt Conveyor is provided with cleaning devices at both head and tail parts, and guide chute, etc.. It can also be equipped with maintenance platform, protective cover, outlet hopper, holdback and other functional parts according to the user requirements. In addition, the user can also customize special belt conveyor according to the operating requirements, such as mobile belt conveyor.

The sand and gravel production line designed and configured by users in Luoyang area of Chengdu Xinshengrun Material has been officially put into production. The production line features: advanced equipment, reasonable grading, environmental protection and energy saving, high output value, high quality of finished products, and strong control ability.

Details

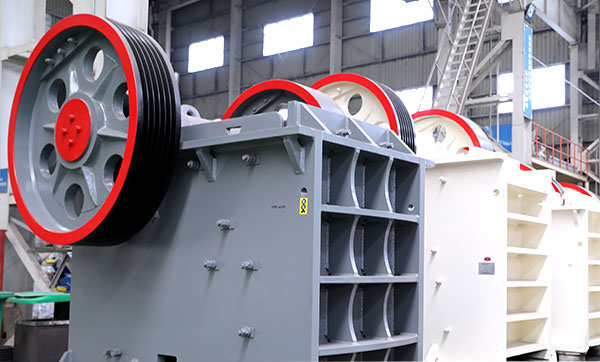

A stone factory in India uses a three-stage crushing process of "jaw crusher + cone crusher + sand making machine" to process basalt (compressive strength 250MPa) into aggregates of various specifications such as 0-5mm, 5-10mm, 10-20mm, etc. The output is 150-180 tons per hour, the finished product has excellent particle shape, and the needle-like content is less than 8%, which meets the IS 383 standard. The wear-resistant parts of the cone crusher are optimized to reduce maintenance costs by 30%. It is suitable for crushing high-hardness ores and provides high-quality sand and gravel aggregates for India's infrastructure.

Details

this river pebble sand making machine production line of Vietnamese users was really put into production in early 2017, and it has been nearly two years now. The level configuration between the equipment in the whole production line is reasonable, smooth operation, and stable production capacity, which is loved by the user

Details

Stone Crusher-sold by certified Suppliers,such as Jaw / Cone / Impact / Mobile Crusher,etc.

GET QUOTE

INQUIRY