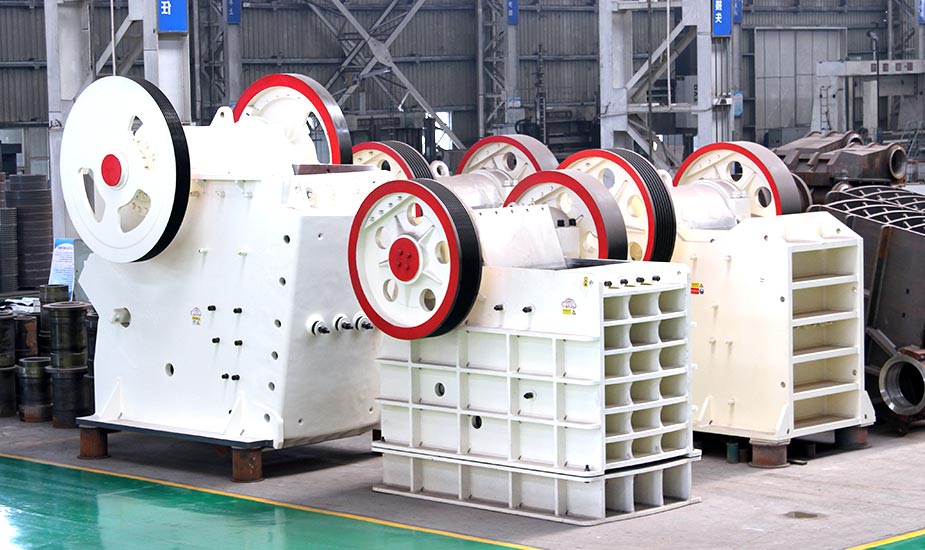

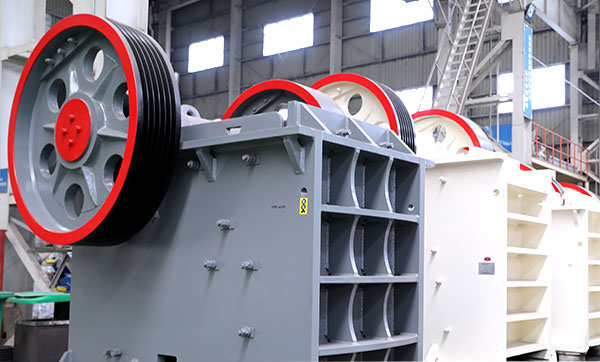

Jaw stone Crusher on structure and production efficiency present advanced modern technologies. Jaw stone Crusher can solve such problems of the existing jaw crushers as low production efficiency, difficult installation and maintenance. At present, Jaw stone Crusher is the ideal coarse crushing machine at domestic market.

The jaw stone crusher obtains a reasonable moment of inertia and a larger crushing stroke by optimizing the equipment structure, crushing chamber type, movable jaw motion trajectory and speed parameters, making the equipment more efficient at the same power consumption and providing customers with a greater return on investment.

In order to ensure that the equipment can operate efficiently when crushing hard materials, the core rotating parts of the C6X jaw crusher, such as high-quality cast movable jaw body, large eccentricity heavy forged eccentric shaft, high moment of inertia cast flywheel and high-strength integral cast steel bearing box, strong power combined with reasonable equipment speed, ensure stable and efficient production of the equipment

The equipment adopts centralized grease lubrication, and can be equipped with manual or automatic grease lubrication system as needed to reduce the difficulty of maintenance, while ensuring that the C6X series jaw crusher operation site is clean and tidy to the greatest extent; the double wedge block adjusts the discharge port, which is simpler and more efficient than the traditional pad plate type discharge port adjustment operation.

The integrated vibration design of the motor and the host integrates the drive unit, reducing space occupancy by 30% and improving the compactness of the structure. It is suitable for automation equipment, medical equipment, etc., taking into account the needs of high efficiency and miniaturization.

The sand and gravel production line designed and configured by users in Luoyang area of Chengdu Xinshengrun Material has been officially put into production. The production line features: advanced equipment, reasonable grading, environmental protection and energy saving, high output value, high quality of finished products, and strong control ability.

Details

A stone factory in India uses a three-stage crushing process of "jaw crusher + cone crusher + sand making machine" to process basalt (compressive strength 250MPa) into aggregates of various specifications such as 0-5mm, 5-10mm, 10-20mm, etc. The output is 150-180 tons per hour, the finished product has excellent particle shape, and the needle-like content is less than 8%, which meets the IS 383 standard. The wear-resistant parts of the cone crusher are optimized to reduce maintenance costs by 30%. It is suitable for crushing high-hardness ores and provides high-quality sand and gravel aggregates for India's infrastructure.

Details

this river pebble sand making machine production line of Vietnamese users was really put into production in early 2017, and it has been nearly two years now. The level configuration between the equipment in the whole production line is reasonable, smooth operation, and stable production capacity, which is loved by the user

Details

Stone Crusher-sold by certified Suppliers,such as Jaw / Cone / Impact / Mobile Crusher,etc.

GET QUOTE

INQUIRY