Vertical coal mill is an advanced coal grinding equipment with excellent performance and strong drying capacity. It integrates the functions of powder making, powder selection and drying. It is widely used in cement, coal, electric power and other industries, especially in the grinding industry. It has become the mainstream equipment in the powder making industry.

Vertical coal mill integrates crushing, drying, grinding, powder selection and transportation. It has a compact layout and occupies an area of about 50% of the ball mill system. It can be arranged outdoors, which greatly reduces investment costs. The system design is simple and reasonable, saving unnecessary equipment investment and reducing the total equipment investment.

The equipment runs stably with little vibration and low noise; the Vertical coal mill is completely sealed and works under negative pressure, with no dust spillage, clean environment, and emission standards far exceeding international standards; equipped with expert automatic control system, it can realize free switching between remote control and local control, which is easy to operate and saves labor.

Xinshengrun takes grinding efficiency, powder drying, wear of wearing parts, and repair and replacement of accessories into consideration to achieve lower energy consumption, stronger drying capacity, lower wear of core parts, and more convenient maintenance, thus saving customers’ equipment operating costs.

Vertical coal millis sealed and operates under negative pressure, ensuring no dust spill, small vibration, low noise, and a more environmentally friendly production process.

The sand and gravel production line designed and configured by users in Luoyang area of Chengdu Xinshengrun Material has been officially put into production. The production line features: advanced equipment, reasonable grading, environmental protection and energy saving, high output value, high quality of finished products, and strong control ability.

Details

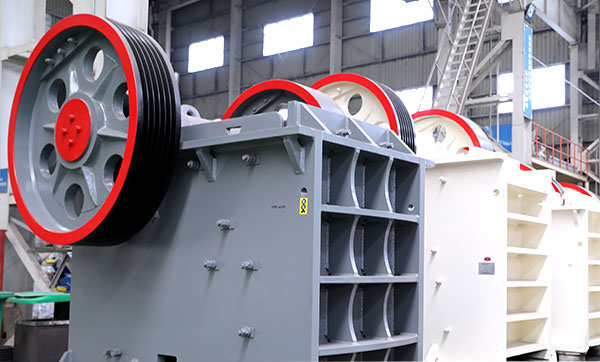

A stone factory in India uses a three-stage crushing process of "jaw crusher + cone crusher + sand making machine" to process basalt (compressive strength 250MPa) into aggregates of various specifications such as 0-5mm, 5-10mm, 10-20mm, etc. The output is 150-180 tons per hour, the finished product has excellent particle shape, and the needle-like content is less than 8%, which meets the IS 383 standard. The wear-resistant parts of the cone crusher are optimized to reduce maintenance costs by 30%. It is suitable for crushing high-hardness ores and provides high-quality sand and gravel aggregates for India's infrastructure.

Details

this river pebble sand making machine production line of Vietnamese users was really put into production in early 2017, and it has been nearly two years now. The level configuration between the equipment in the whole production line is reasonable, smooth operation, and stable production capacity, which is loved by the user

Details

Stone Crusher-sold by certified Suppliers,such as Jaw / Cone / Impact / Mobile Crusher,etc.

GET QUOTE

INQUIRY